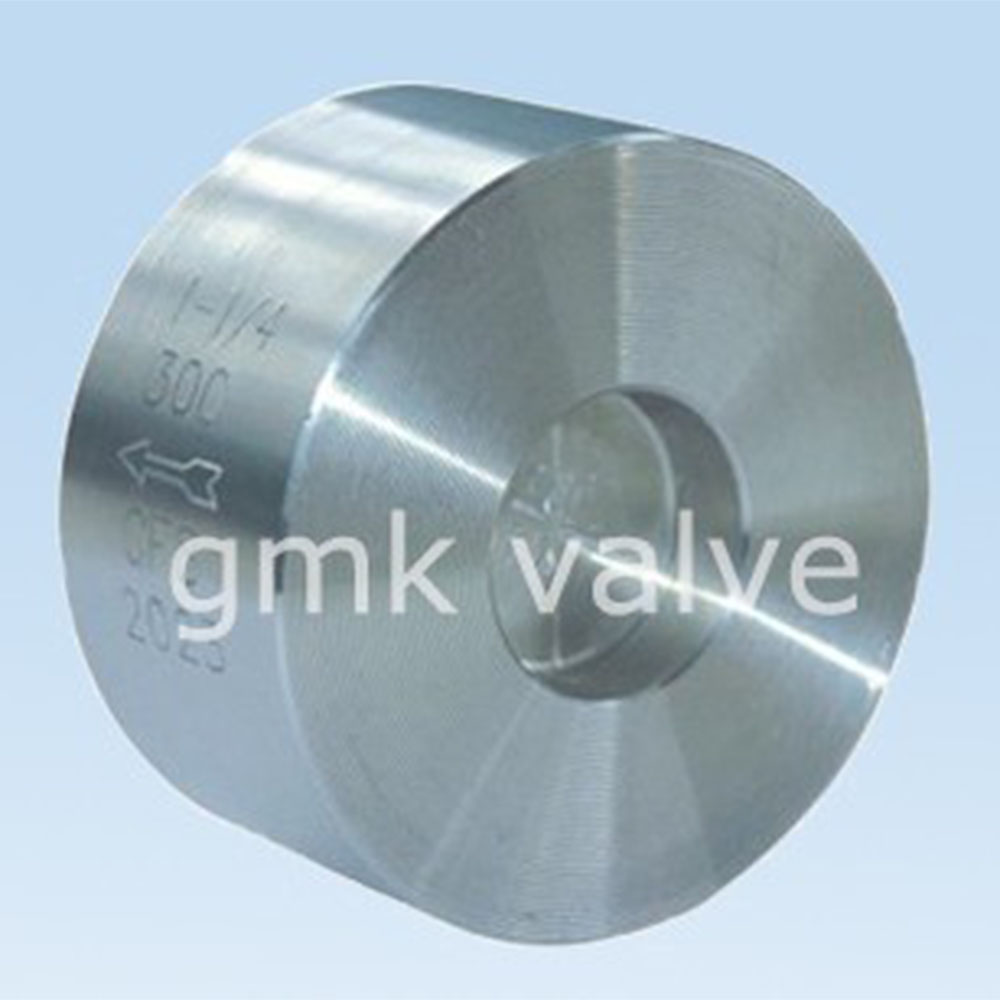

GMK Swing Check Valve

A GMK swing check valve consists of a disc that is attached to a hinge or shaft that can swing back and forth. The disc can slide off the seat in order to allow water to flow in one direction, and then it can slide back onto the seat in order to prevent water from flowing in the opposite way. The capability of the valve to close is impacted by the mass of the disc as well as the flow rate when operating in reverse. Check valves are actuated by a lever and a weight or by a lever and a spring. It is usual practice to attach a lever in conjunction with a weight or a spring in order to achieve the highest possible level of efficiency. Installing a lever and weighted swing check valve is recommended whenever there is a possibility of water hammer occurring at normal flow rates in a given environment. If you have high pressure, low back pressure, and a high flow rate, your best option is a lever and external spring swing check valve. This type of check valve has the ability to swing open and close quickly. It is important to keep in mind that a swing check valve’s disc does require occasional cleaning, which means that the valve is not completely maintenance-free. A lever is generally installed in order to facilitate simple visual inspection as an additional convenience. As a result of this, swing check valves are frequently utilized in locations that are frequently visited by people.

- Size:2″~48″

- Rating:150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5,C12,C12A, CF8, CF8M, CF3, CF3M, CN7M,Alloy 20,B148,UB6 ,Hastelloy C etc

- Connection:Flanges, RTJ flange, butt weld, hub end, groove