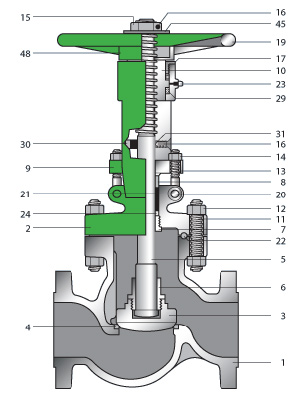

GMK Pressure Seal Globe Valve

As the name implies, GMK Pressure Seal Valves are designed for use in high-pressure, high-temperature environments with virtually any fluid, with the exception of those with the potential for severe choking. The construction materials and design of pressure seal valves make them ideal for usage in nuclear steam generating stations, industrial/chemical plants, and thermal power plants. When it comes to flow passage and sealing, Pressure Seal Valves excel, while also conserving weight, being simple to install, and requiring little to no upkeep.

Even when a large amount of pressure is flowing through the valve, the stem of a GMK globe valve is able to function normally without being forced to the side. There is less wear and tear on both the packing and the stem itself because the stem does not turn. Because of this, the valve is able to firmly and smoothly close even when subjected to high pressures.

- Size:2″~24″

- Pressure:ANSI #900~#2500

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6, Hastelloy C etc

- Connection:RF flange, RTJ flange, butt weld, hub end, groove

- Operate:Handwheel, wormgear, gearbox, penumatic actuator