To close off a pipe or other fluid source, a knife gate valve can be used. This controls the flow of fluid through the pipes. Its primary application is in a pipe network used to transport gas or liquid. In particular, the piping system through which the high-density material flows. A knife gate valve gate is designed with sharp edges that can slice through the pipe’s high-density material. When the time comes, the pressure drop mechanism of this valve will shut off the flow. This guarantees a 100% leak-proof seal on the valve.

Benefits

- When the knife gate valve is in its fully open position, it enables a flow adjustment that is very slow and delicate.

- In this valve, flow can move in any direction.

- The location of the valve is completely discretionary. The flywheel, on the other hand, needs to be positioned on a strut that is vertical with respect to the ground.

- Even for pipes with large nominal sizes, it may be possible to shorten the overall length of the valve.

- It is readily available, at a low cost, and at any location you want.

- There are varieties that are able to tolerate tremendous amounts of pressure.

- Simple to take care of.

FEATURES:

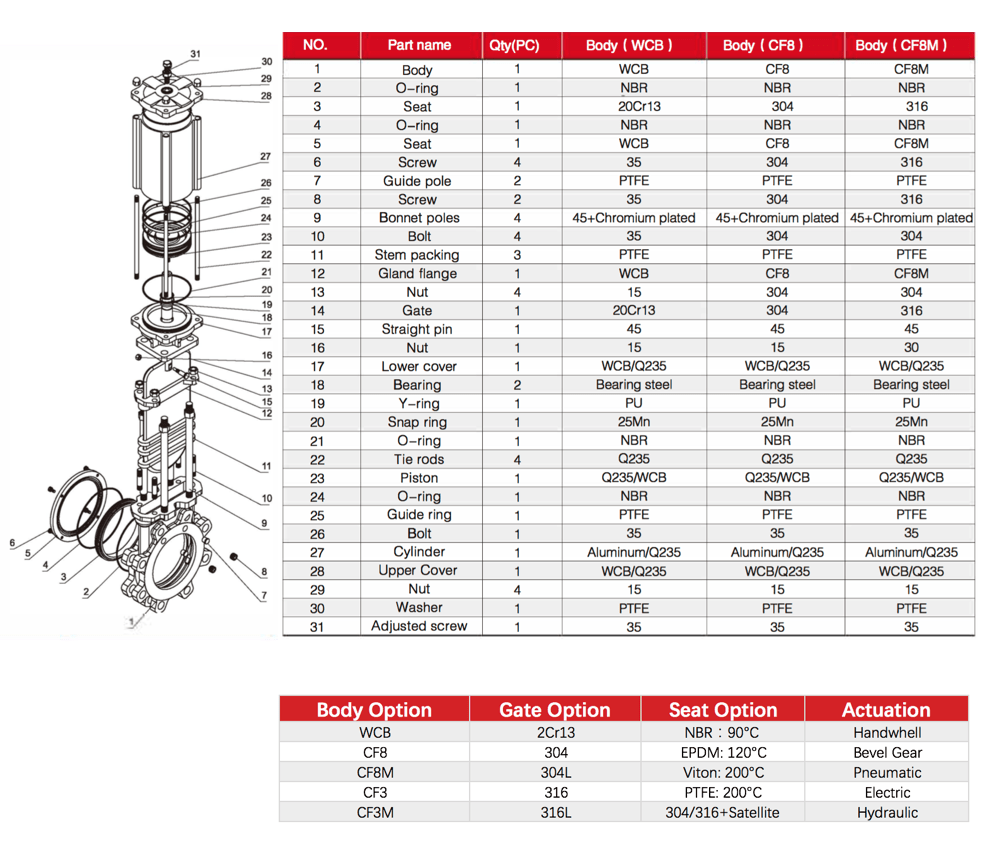

The knife gate valve is a unidirectional wafer knife edge gate valve used on industrial pipeline for on-off operation. The structure of body and seat eliminates clogging shutoff for flow with fine particles. Additionally, beveled knife edge helps the gate cut through thick media easily.

According to different working situation: non-rising stem knife gate valve, wafer knife gate valve, lugged knife gate valve, pneumatic knife gate valve, electric knife gate valve, manual knife gate valve and bevel gear knife gate valve are all available.

Body:

- Guide claws design at the port bottom for gate fixture, instead of a groove, eliminates any potential clogging when valve shutoff.

Integral body design ensures smooth flow, easy assembly and smaller shell leakage possibility.

Gate:

- Beveled knife edge provides strong cutting stress and tight sealing.

PTFE resilient point guider above the port prevents metal-metal contact between gate and body.

Gate thickness can be increased to meet higher pressure.

Seat:

- Side-entry seat is replaceable, reducing the cost of maintenance.

Preloaded seat is adjustable to meet different sealing class and compensate normal seat wear.

Seat retainer covers the side of seat and prevents seat from direct flow flushing.

Other:

- Double thrust bearing minimize the torque required for operation.

Stem Cover is available

Grease Nipple is available

Bearing Cover is available

Application:

- Pulp & Paper / Water & Waster Water / Mining / Metallurgy / Petrochemical / Printing & Dying / Pharmacy / Beverage & Food