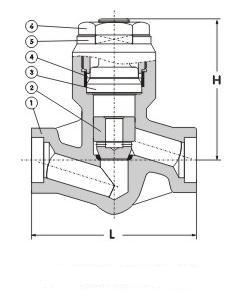

Forged Steel Pressure Seal Check Valve

The most recent software-based analytical techniques were used throughout the design process of GMK’s forged pressure seal check valves. All of the projects are assessed utilizing techniques for three-dimensional solid modeling throughout the design phase. The benefits include a decrease in the amount of time and expense spent developing the product, as well as an improvement in product quality. In the development stage, we utilize something called finite element analysis, or FEA, to make sure the valve will fulfill all of the design performance criteria. The valves are inspected for any difficulties with their functionality, as well as any material deformation or flow-related stresses.

- Size:1/2″-2″

- Pressure:900LB-2500LB

- Material:A105,LF2,F11,F22,F304,F304L,F316, F316LF904L Allay20 ect

- Connection:NPT thread,Socket weld,Flange