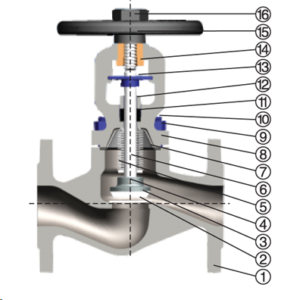

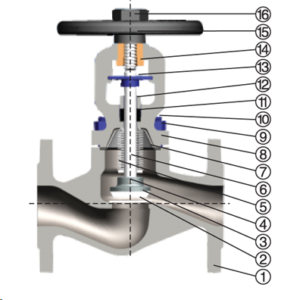

GKM DIN Bellows Seal Globe Valve is leakage free. An automated seam welding process is used to construct a metal barrier to ensure no leakage in GMK DIN Bellows Seal Globe Valve. The metal barrier is placed between the fluid medium and the surrounding environment. It incorporates a bellows structure on the inside, and the lower end of the stainless-steel bellows is welded to the valve stem in order to prevent the process fluid from eroding the valve stem. It is ideally suited for use in pipelines transporting steam as well as other media such as flammable, explosive, heat transfer oil, high-purity, and toxic substances.

Benefits

- It is a product with a reasonable design, dependable sealing function, and a lovely aesthetic appearance.

- Sealing surfaces surfaced with Co-based cemented carbide, which provides high wear and corrosion resistance, low friction, and long service life.

- The valve stem has been quenched, tempered, and nitrided on the surface, giving it excellent resistance to corrosion and friction.

- It’s easier to understand the valve lift position indicator.

- To accommodate a wide range of technical requirements, the kind of material, the number of flanges, and the size of the butt welds are all fairly chosen based on real working circumstances or user requirements.