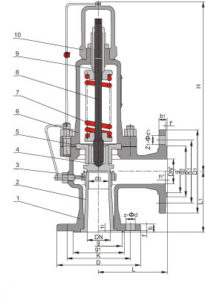

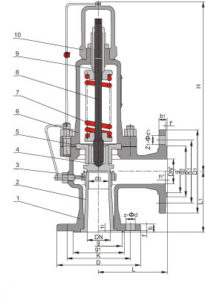

Our Closed Spring Loaded Low Lift Type Safety Valve has a disc holder to maximize the force exerted by the fluid, which leads to a disc lift that is almost immediate. To control the blowdown adjust the ring that surrounds the nozzle. You may increase the disk without risk since the components that make it up, as well as the distance that separates the disc holder from the guide, the spindle, and the adjustment screw, are all adequate. Lapping and precision machining provide seats with a surface that is particularly flat and smooth, hence increasing the level of safety. Our every single product is put through exhaustive testing and examination.

Benefits

- Allows for an immediate halt to the flow of

- Seals effectively below the valve’s breaking pressure to prevent leakage.

- Not activated by backflow pressure or gravity.

- Achieves reliable valve closing in any position

- Maintaining a system’s fluid or gas flow is facilitated without the risk of backflow becoming an issue.

- Springs may function across a broad variety of temperatures.

|

NO.

|

Name of part

|

A41Y-160

A41Y-320 Materials

|

A41Y-160P

A41Y-320P Materials

|

A41Y-160R

A41Y-320R Materials

|

|

1

|

Flange

|

35/35CrMoA

|

2Cr13

|

1Cr18Ni9Ti

|

|

2

|

Nozzle

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

3

|

Body

|

35/40

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

4

|

Disc

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

5

|

Guide sleeve

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

6

|

Spring

|

50CrVA

|

50CrVA Coated Teflon

|

50CrVA Coated Teflon

|

|

7

|

Stem

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

8

|

Bonnet

|

ZG230-450

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

9

|

Adjusting bolt

|

45

|

2Cr13

|

2Cr13

|

|

10

|

Cap

|

ZG200-400

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

|

Sealing surface of seat and disc

|

|

Co Depositing stellite

|

Dimension(mm)

|

Type

|

(DN)

|

do

|

d

|

M

|

D

|

K

|

Z- d

|

b

|

d1

|

M1

|

D1

|

k1

|

Z1-d1

|

b1

|

L

|

L1

|

H

|

|

A41Y-160

(

|

15

|

8

|

20

|

M24*2

|

95

|

60

|

3-18

|

20

|

/

|

M33*2

|

36

|

/

|

/

|

/

|

50

|

80

|

85

|

|

20

|

10

|

25

|

M27*2

|

95

|

60

|

3-18

|

20

|

/

|

M33*2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

25

|

12

|

28

|

M33*2

|

105

|

68

|

3-18

|

20

|

/

|

M33*2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

A41Y-160

|

10

|

8

|

18

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

20

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

27

|

M33*2

|

105

|

68

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

28

|

M33*2

|

105

|

68

|

3-18

|

20

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12,14,16

|

37

|

M42*2

|

115

|

80

|

4-18

|

22

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

40

|

20

|

47

|

M52*2

|

165

|

115

|

6-26

|

28

|

65

|

M80*3

|

200

|

145

|

6-29

|

40

|

165

|

165

|

350

|

|

50

|

25

|

58

|

M64*3

|

165

|

115

|

6-26

|

32

|

80

|

M100*3

|

225

|

170

|

6-33

|

80

|

165

|

165

|

380

|

|

A41Y-320

|

10

|

8

|

18

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

27

|

M33*2

|

105

|

68

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

30

|

M36*2

|

110

|

75

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

35

|

M42*2

|

115

|

80

|

4-18

|

22

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12,14,16

|

41

|

M48*2

|

135

|

95

|

4-22

|

25

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

40

|

20

|

58

|

M64*3

|

165

|

115

|

6-26

|

32

|

65

|

M80*3

|

200

|

145

|

6-29

|

40

|

165

|

115

|

350

|

|

50

|

25

|

70

|

M80*3

|

200

|

145

|

6-29

|

40

|

80

|

M100*3

|

225

|

170

|

6-33

|

50

|

165

|