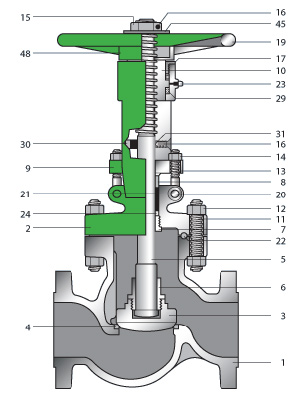

GMK Cast Steel Globe Valve

When it comes to controlling the flow of liquids in a pipeline, a globe valve is the tool of choice. It is installed at the end of a pipe and used to regulate or halt the flow of a fluid or gas via that pipe. The globe shape of a globe valve’s body is where the term comes from, as an internal baffle keeps the two portions of the valve from touching. These valves can be employed when the pressure drop across the valve is not a limiting factor, despite having slightly higher-pressure dips than gate/ball valves. Besides their more common name, globe valves are also sometimes called throttle valves. A globe valve’s primary functions are flow control and isolation. A disk-like part that can rotate and a ring seat that remains stationary make up the sphere-shaped body. A globe valve has a seat that runs centrally and perpendicular to the pipe, and it uses a disc or plug to seal off the opening in the seat. The design of a globe valve allows it to function either way.

- Size:2″~20″

- Rating:150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6, Hastelloy C etc

- End connection:Flanges, RTJ flange, butt weld, hub end, groove

- Operation:Handwheel, wormgear, gearbox, pneumatic actuator