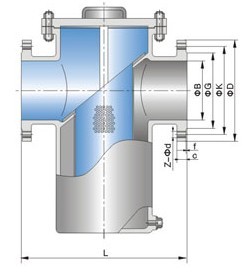

GMK Basket Strainer

The installation of a basket strainer in a horizontal pipe is done so that debris can be removed from the pipe. After that, the impurities are removed by a filter before being passed on to the subsequent mechanisms, such as pumps, valves, and traps. It is common a practice to use strainers that are equipped with baskets in order to reduce the risk of causing harm to machinery as a result of debris in the pipeline. The presence of dirt or other foreign particles in the process fluid is an illustration of the kind of undesired material that can be found in the fluid. Strainers in the form of baskets are frequently utilized in horizontal pipelines and a variety of other applications where significant quantities of fluid are being transported through the system. Installed upstream of devices such as pumps, control valves, and traps, strainers remove particles that could potentially cause damage to the downstream equipment. They are capable of operating on their own, or they can be connected in a chain to increase the filtration capacity. There is the option of a simplex or a multi-chamber architecture (simplex and multi-chamber, respectively).

- Size:2″-40″

- Pressure:150LB, 300LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M ect

- Connection:Flanges